VOTCO Corp a Trusted Partner of Oliver + Batlle

Discover the best industrial equipment solutions at VOTCO Corp - Your reliable partner!

Tank Mounted Single and Multi-Shaft Mixers and Agitators

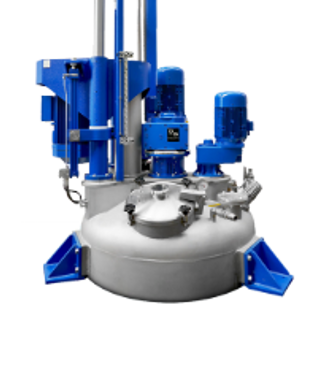

POLIMIX DPS

FINISHING TANKS TA

POLIMIX DPS-OR

POLIMIX DPS-Multi (one, two or three shaft) mixer – disperser for medium / high viscosity products.

Cylindrical shell .

Designed for batches from 500 gallons to 4000 gallons, installed power up to 350 HP.

Designed as a multi-functional unit, the POLIMIX disperser has a standard mixer/disperser which can be complemented by an anchor sweep s

POLIMIX DPS-Multi (one, two or three shaft) mixer – disperser for medium / high viscosity products.

Cylindrical shell .

Designed for batches from 500 gallons to 4000 gallons, installed power up to 350 HP.

Designed as a multi-functional unit, the POLIMIX disperser has a standard mixer/disperser which can be complemented by an anchor sweep shaft. Depending on the application, a third shaft with X-blade impellers can be added.

Applications

- Adhesives

- Glues

- Tintometric base

- Waterproof coatings

- Lacquers

- Inks

- Water based paints

- Solvent based paints (automotive, decorative coatings).

Advantages

- User-friendly and ergonomic.

- Easily integrated into an automatic manufacturing process.

- Absolute control of fumes and suspension particles, thanks to closed shell design.

- Robust construction.

- Wide range of accessories, to adapt the mixer to specific needs of the production process.

Accessories

- Raising and lowering system of the disperser shaft.

- Operation under vacuum or pressure.

- Inerting system

- Instrumentation for product parameters control (pressure/temperature) in real time.

- Cleaning systems, manual or automatic (CIP)

- Vapors condenser

- High reliability weighing system.

- Vessels with cooling jacket or limpet coil (cooling / heat).

- Different inner finishing in accordance with production requirement.

- Process control system.

- Configuration ATEX ZONE O.

- XP (US Models)

POLIMIX DPS-OR

FINISHING TANKS TA

POLIMIX DPS-OR

Twin shaft coaxial mixer – disperser with cylindrical vessel (DPS-OR) , or conical vessel (DPS-ORC) , to process concentrated products in a very short time.

Volumes from 150 gallons to 4000 gallons, dependent on vessel shape, installed power up to 400 HP.

High powered mixing-dispersing high-speed shaft, complemented with a second, anchor s

Twin shaft coaxial mixer – disperser with cylindrical vessel (DPS-OR) , or conical vessel (DPS-ORC) , to process concentrated products in a very short time.

Volumes from 150 gallons to 4000 gallons, dependent on vessel shape, installed power up to 400 HP.

High powered mixing-dispersing high-speed shaft, complemented with a second, anchor sweep shaft, fitted with bottom and side-wall scrapers. The dissolver has been designed to be integrated into an automatic manufacturing process.

Applications

- Adhesives

- Glues

- Waterproof coatings

- Lacquers

- Inks

- Water based paints

- Solvent based paints (automotive, decorative, coatings)

Advantages

- High efficiency in dispersion process.

- High efficiency in solids loading (automatic loading capacity up to 410 Tn/h).

- User friendly and ergonomic.

- Easily integrated into an automatic manufacturing process.

- Absolute control of fumes and suspension particles, thanks to closed shell design.

- Robust construction.

- Wide range of accessories, to adapt the mixer to the specific needs of the production process.

Accessories

- Raising and lowering system of the disperser shaft.

- Operation under vacuum or pressure.

- Instrumentation for product parameters control.

- Cleaning systems (CIP).

- Vapors condenser.

- Weighing system.

- Vessels with cooling jacket or limpet coil.

- Parameters control system for machine and product.

- Configuration ATEX ZONE O

- XP (US Models)

FINISHING TANKS TA

FINISHING TANKS TA

FINISHING TANKS TA

Finishing Tanks-for mixing, finishing and tinting of coatings,

Volume between 250 gallons and 5300 gallons.

Mixing groups with different blade profiles, in accordance with process needs and technical characteristics of the product.

Applications

Standard machines (max. 6000 cp , SPG. 1.6 kg/dm3 ) :

- Adhesives

- Glues and varnishes

- Phytosanitary

- Auto

Finishing Tanks-for mixing, finishing and tinting of coatings,

Volume between 250 gallons and 5300 gallons.

Mixing groups with different blade profiles, in accordance with process needs and technical characteristics of the product.

Applications

Standard machines (max. 6000 cp , SPG. 1.6 kg/dm3 ) :

- Adhesives

- Glues and varnishes

- Phytosanitary

- Automotive paints

- Decorative Paints

- Liquid inks

Advantages

- High mixing efficiency thanks to eccentric design, minimizing mixing time and guaranteeing homogeneity of tinting process.

- New generation helical gear box allowing to minimize equipment height.

- User friendly and ergonomic.

Accessories

- Two fixed speed agitator or variable speed by frequency inverter.

- Blades sabre or « paddle » as per products viscosity and special profiles.

- Vapors condenser

- Weighing system

- Cleaning system

- Industrial or mirror internal polish of the vessels

- Discharge automation

- Parameters control system for machine and product.

product brochures

Downloadable pdf

Files coming soon.

Copyright © 2024 VOTCO Corp - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.